Your contact to us

Division Appliances:

Vacuum-packed food can be prepared particularly gently:

first pack your food with the vacuum drawer and then cook it at a low temperature in the steamer.

In this way, vitamins and minerals are optimally preserved and the vegetables remain crunchy.

Your steaks will be exceptionally tender and the flavour intense.

The sealing process

Areas of application

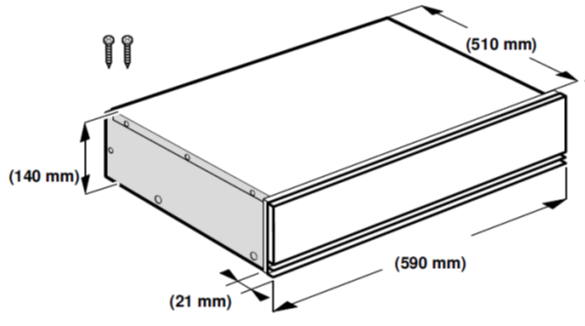

With a height of only 140 mm, the vacuum drawer can also be retrofitted into almost any kitchen unit.

For our OEM customers, we can adapt the vacuum drawer to the individual dimensions and design of your appliance line on request.

Through the Appliances and Ventilation & Surfaces divisions, we develop and produce various downdraft systems for a wide range of cooktop variants, including electric cooktops and cooktops with induction or radiant heating technology.

For this purpose, we use our expertise in appliance and component manufacturing as well as in the development and optimisation of blower systems.

The advantages:

We develop and manufacture complete cooker hoods and extractor hoods or individual components for both the gastronomy and household appliance industries. We customise the design and functionality of the hoods, and develop the integrated fan system with optimised performance and noise levels.

The shock freezer enables the shock freezing of food and dishes within a few minutes and is indispensable to the catering industry. In addition to the required temperature management, optional areas of product customisation are offered.

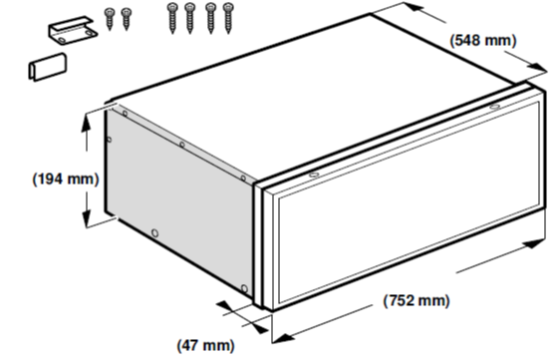

Our cooling drawers are suitable for a wide variety of practical applications, including cooling medicines in the medical industry and keeping heat-sensitive food and special liquids fresh in private households and small-scale catering. The refrigerated drawer corresponds to the standard installation dimensions, allowing it to be easily integrated into application series.

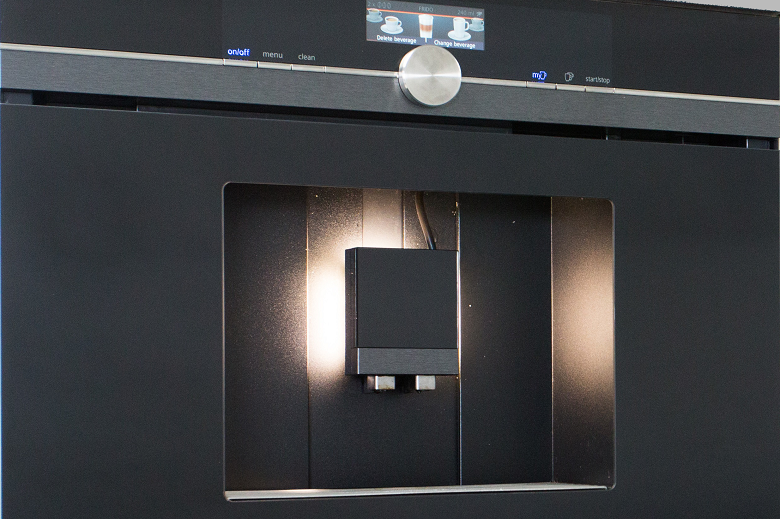

Gronbach exploits its extensive expertise in the development and production of high-end built-in coffee machines and espresso machines for gastronomy, offices and private use.

We supply a wide range of functional assemblies and design-oriented individual components, e.g. drip plates, front panels, side panels, frames, operating elements and racks. Both in terms of design and the technical specifications of the fluid system, we focus entirely on the wishes of our customers.

On behalf of our customers, we develop and manufacture functional and design-oriented cooktops for many types of heating, including electric cooktops, cooktops with induction or radiant heating technology, and cooktops with downdraft extractors. We work together with renowned suppliers of glasses and electronics for this purpose.

Warming drawers are ideal for preheating dishes or keeping food warm. They can be combined with other household appliances, e.g. ovens, steam cookers or built-in fully automatic coffee machines in the kitchen front for a uniform visual image, but can also be adapted according to alternative customer-specific specifications.

Our warming drawers were developed in-house and are mass-produced on an OEM basis for our brand customers and are constantly being developed to meet new demands in the household appliance sector.

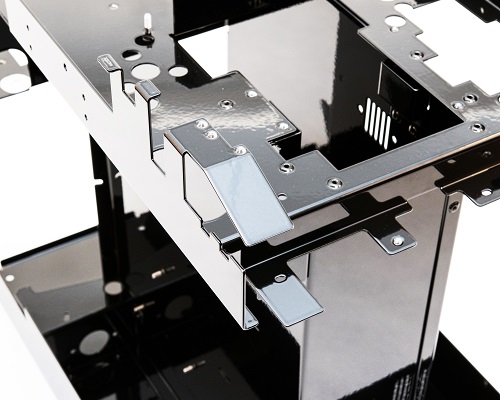

The racks and fronts are designed, mass-produced and finally assembled according to the customer specifications of well-known appliance manufacturers. We either manufacture the necessary assembly components ourselves or obtain them from our affiliated supply partners. They are characterised by a high degree of precision and robustness.

Depending on the customer’s order, we realise a wide variety of decors, e.g. made of glass and/or aluminium, and also integrate user-oriented operating elements.

Partial-and full-extension rails for ovens and range cookers represent a central product group in our portfolio, enabling a particularly stable and low-noise gliding movement for the end user. Outside the household appliance industry, our drawer rails are adaptable for alternative fields of application, e.g. for the furniture industry.

We manufacture mechanical and electromechanical flap door hinges for installation on the door or appliance side, primarily for the household appliance industry. We adapt these according to the installation situation and the requirements of our customers for a perfect fit. Through our platform, we are able to adapt our solutions not only to new household appliance models, but also to alternative application areas and industries.

Division Appliances: