Your contact to us

Division Surfaces:

FAQs

- Order volumes [

- Requests from private individuals

Please take into account that our production is geared towards medium to large series production. We are therefore unable to process requests for very small quantities for economic reasons.

We ask for your understanding that we cannot consider requests from private individuals of any kind.

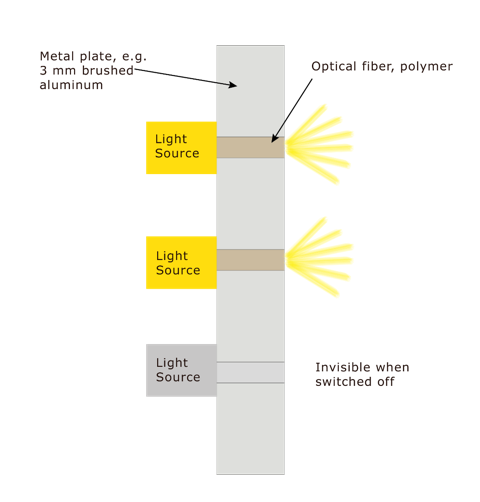

Perforated surfaces that enable the metal to communicate through integrated light controls or sensor technology.

Perforated surfaces that enable the metal to communicate through integrated light controls or sensor technology.